High-precision CNC hardware parts service

For all your processing needs

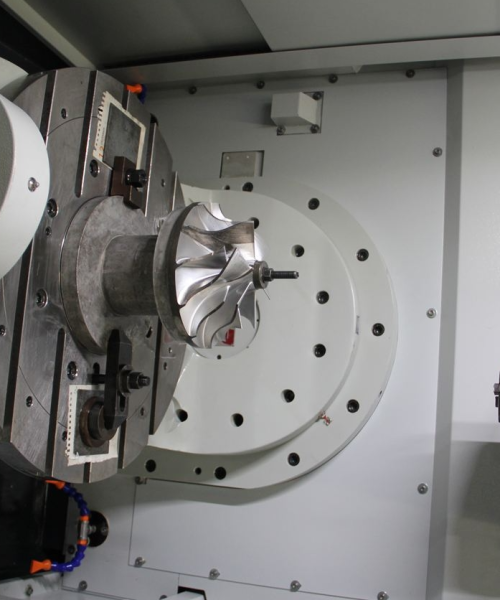

In the realm of complex and time-critical machined components, 5-axis CNC machines stand out for their exceptional flexibility and rapid production capabilities. The team at XLC, with their extensive experience, is dedicated to transforming your innovative ideas into tangible products. We excel in delivering both rapid prototypes and high-quality end-use parts, especially for applications where safety and reliability are of utmost importance. Our advanced 4-axis and 5-axis milling technologies ensure that we can produce parts with intricate geometries and precise tolerances. Additionally, our comprehensive suite of CNC machining services, encompassing 3-axis milling, CNC turning, and EDM, is designed to meet a wide range of manufacturing needs. To explore how we can support your project, visit our detailed CNC machining service page for further information.

Five advantages of XLC company’s 5-axis precision machining

Among many precision machining manufacturers, the following 4 reasons are why you should choose us

Quick turnaround

With 15 in-house 5-axis machines, we have the ability to create your prototypes and production parts in days.

Quick quote and design

Our company has 10 technical engineers who have been in the industry for 20 years. They can quickly make quotations and provide technical discussions.

Quality assurance

A variety of measuring equipment, three-dimensional coordinates, projectors, hardness testers, flaw detectors, etc. to provide customers with high-quality products

industry compatibility

Our products cover aerospace, automobiles, new energy, ships, etc. We have close cooperation with various industries

What is 5-axis CNC Process

Five-axis technology is an advanced machining technology that achieves high-precision and high-efficiency processing of complex parts by simultaneously controlling the movement of five axes.

So how does the five-axis work?

The working principle of five-axis machining primarily relies on its multi-axis linkage control system. Specifically, a five-axis CNC machine tool achieves comprehensive machining of workpieces by simultaneously controlling three linear axes (X, Y, Z) and two rotary axes (usually the A and C axes). This linkage capability allows the cutting tool to rotate and tilt in multiple directions, thereby enabling the efficient and precise machining of complex surfaces and three-dimensional components.

In the process of five-axis machining, it is first necessary to create a 3D CAD model of the required component, which is then exported to CAM software to generate G-code. The G-code contains instructions for the CNC machine, controlling the movement of the cutting tool and the workpiece. In this way, five-axis machining can complete the machining of multiple faces of a workpiece in a single setup, thereby saving manufacturing time and costs.

Moreover, the high precision and stability of five-axis machining are attributed to its advanced CNC systems and interpolation algorithms. These systems can accurately control the motion trajectories of each axis, ensuring the synchronization and coordination of the machining process.

Characteristics of five-axis machining products

Throughout manufacturing, there are many types of parts involved. The five-axis machining process is suitable for products that require high precision and complex geometries, such as aerospace parts, precision molds, and high-performance automotive components.

Five-axis machining parts

The use of five-axis machining technology can significantly shorten the processing cycle of mold parts and improve the processing efficiency and quality of mold parts. It can also reduce the number of assembly times, effectively improve the assembly accuracy of components, and reduce positioning errors. This helps to produce mold parts with high dimensional accuracy and low surface roughness, meeting the stringent requirements of precision molds.

Auto parts

With the continuous innovation of automobile design, more and more complex parts require high-precision processing. Five-axis machining centers can easily meet these challenges, such as processing engine blocks, crankshafts and other components with complex shapes and variable curvatures, meeting the needs of the automotive manufacturing industry for high-precision and high-strength components.

Choose the right five-axis equipment for processing

The types and movement modes of five-axis CNC equipment are different. Choosing suitable rigid processing equipment has a great impact on the stability and output of parts. The following will introduce two popular five-axis processing equipment with motion methods.

Full 5-axis machine tool

The full five-axis machine tool controls the coordinated work of five independent motion axes (three linear axes X, Y, Z and two rotary axes A, B or C) through the CNC system to achieve all-round processing of the workpiece. Linear axes are responsible for the spatial movement of the workpiece, and rotary axes enable it to rotate and tilt to machine from multiple angles. Combined with the tool path generated by CAM software, the full five-axis machine tool can efficiently and accurately complete multi-faceted processing of complex parts in one clamping, and is widely used in aerospace, precision molds and other fields.

3+2 five-axis machine tool

A 3+2 five-axis machine tool achieves planar movement of the workpiece through three linear axes (X, Y, Z), while two rotary axes (usually the A and C axes) are used for fixed-angle tilt and rotation. This configuration allows the machine tool to perform complex cuts at specific angles, but the rotating axis does not participate in continuous machining. It is suitable for processing parts with specific angular features, such as inclined holes and inclined surfaces, and is suitable for medium-complexity processing tasks.

5-Axis CNC

Machining FAQ's

The axes, in terms of CNC machining, determine the number of directions that the cutting tool can move in when producing parts. There are the three-dimensional axes, and the 5-axis machine’s cutting tool can also rotate to approach the part from two directions, which serve as two additional axes.

Because of the flexibility offered by 5-axis machining, it should be used to create the most complex shapes and details in parts. The stability of the tool also provides a smoother and more consistent finish.

5-axis CNC machining is one of the most advanced manufacturing technologies available, so it can produce some of the tightest tolerances possible, even on complex and detailed parts.