CNC Turning Services

Global Swift Delivery, 10-Day Dream Turned Reality.

In the precision machining domain of XLC, CNC turning services stand as one of the core offerings. This technology focuses on the rotation of workpieces through high-precision lathes controlled by a numerical control system. Unlike CNC milling, where the cutting tool rotates, in turning the workpiece spins while the tool remains stationary, making this process particularly suitable for crafting parts with complex geometric shapes that are rotationally symmetric.

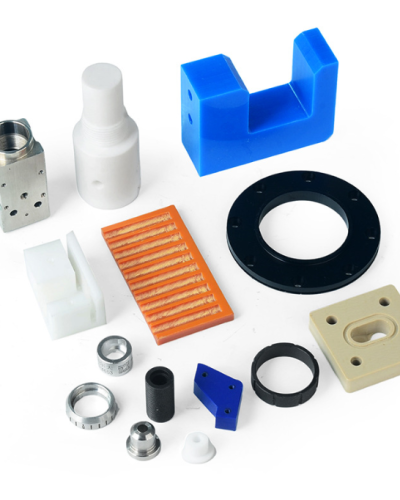

Our services extend beyond metals such as aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium, and nickel alloys, to include a range of engineering plastics like nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, and PEEK. This diversity ensures that we can meet the specific needs of various industries and applications.

XLC's CNC turning services place a special emphasis on custom non-standard manufacturing, meaning we can provide tailored solutions according to the individualized needs of our clients. Our CNC lathes, also known as turning machines, are key equipment for achieving these precision machining tasks. With these advanced machines, we can ensure that each product meets the highest quality standards, satisfying our clients' stringent requirements for precision machining.

Whether it's small batch production or mass manufacturing, XLC is capable of providing a swift response to ensure projects are completed on time. Our global distribution network guarantees rapid logistics services, allowing our clients' products to reach their destinations quickly. Choosing XLC means selecting a reliable partner, an expert in providing precision machining and custom non-standard manufacturing solutions.

Applications of CNC Turning

1. Expertise in Cylindrical Parts: CNC turning technology is the preferred method for producing round or cylindrical components. This technique enables the creation of these parts with high speed and precision, ensuring excellent repeatability, which is crucial in production environments that require a large number of identical parts.

2. Versatility in Processes: CNC turning is not limited to processing parts of a certain shape. It also encompasses a range of machining processes, including drilling, boring, threading, and knurling. This versatility allows CNC turning to meet the diverse needs of various industries and applications.

3. Guarantee of Professional Quality: Through automation and precise control, CNC turning ensures a high standard and consistency in the machining process. This professional quality is one of the core strengths of XLC's CNC machining services.

4. Flexibility in Customization: XLC's CNC turning services place a special emphasis on customization to meet the individual needs of our clients. This flexibility allows us to cater to special requirements and provide unique products for our customers.

5. High Standards in Precision Machining: By utilizing advanced CNC lathes, XLC ensures that each product meets the highest quality standards, satisfying the stringent requirements for precision machining.

6. Rapid Response in Production Capacity: Whether it's small batch production or mass manufacturing, XLC is capable of providing a swift response to ensure projects are completed on time.

What is CNC turning?

Numerical Control Machining (NC Machining), often referred to as CNC (Computer Numerical Control) Machining, is an automated machining process that utilizes computer programs to control the movement of machine tools. Here is a detailed explanation of how it works:

1.Design and Programming:

Engineers or designers first use CAD (Computer-Aided Design) software to create a 3D model of the part.

Then, CAM (Computer-Aided Manufacturing) software is used to convert the design into instructions that the machine can understand. These instructions include cutting paths, speeds, depths, tool selection, etc.

Generating G-Code:

The CAM software translates the manufacturing instructions into G-code, a programming language that the machine can interpret. G-code contains all the necessary information to control the machine's movements.

2.Machine Control Unit:

The G-code is loaded into the machine's control unit (CNC controller). This control unit is the brain of the machine, responsible for interpreting the G-code and controlling the machine's various axes.

3.Machine Movement:

According to the G-code instructions, the CNC controller precisely moves the machine's axes. In turning, this typically involves the X-axis (lateral) and Z-axis (longitudinal).

The relative movement between the tool and the workpiece is controlled by the machine to achieve the required cutting actions.

4.Tool Path:

The tool moves along a predetermined path, removing material to form the desired shape of the part. The tool's path is determined by the instructions in the G-code.

5.Automatic Tool Change:

When different tools are needed or different machining operations are required, the machine can automatically change tools. This is usually achieved through a tool library and an automatic tool changer on the machine.

6.Machining Monitoring:

During the machining process, the CNC system continuously monitors the status of the machine, including tool wear, cutting forces, temperature, etc., to ensure the stability and safety of the machining process.

7.Completion of Machining:

Once all the machining steps are completed according to the G-code, the machine will stop moving, and the machining process is finished.

8.Post-Processing:

After machining, the part needs to be removed from the machine for necessary post-processing, such as cleaning, deburring, heat treatment, or surface finishing.

The advantages of CNC machining include high precision, efficiency, repeatability, and flexibility. It is capable of producing parts with complex shapes and is suitable for both small batch production and mass manufacturing. CNC machining is widely used in industries such as automotive, aerospace, mold making, medical devices, and electronic equipment.

CNC Metal Turning

XLC specializes in providing CNC turning services, proficient in machining a variety of metals including aluminum. Our technological capabilities extend to processing metals such as magnesium, steel, stainless steel, brass, copper, bronze, titanium, and nickel alloys.

CNC turning technology excels in the fabrication of mechanical components and aesthetic parts, which are often crafted from aluminum, a metal that is highly machinable. Aluminum is the material of choice due to its exceptional workability. Through CNC turning, we are able to manufacture aluminum parts that are both strong and precise, while also ensuring a high level of surface smoothness.

CNC Plastic Turning Services

XLC's precision machining expertise extends beyond the realm of metals to include professional CNC turning services for plastic components. Our services cover a wide range of plastic materials, including but not limited to Nylon, Polycarbonate, Polyurethane, Polypropylene, PMMA (commonly known as Acrylic), PTFE (also known as Teflon), PEI (Polyetherimide), and PEEK (Polyether Ether Ketone).

These materials can achieve a higher level of precision and surface finish through the CNC turning process compared to 3D printing, making them suitable for the production of plastic parts that require exact dimensions and surface treatment. XLC's CNC plastic turning services can meet the needs of everything from prototype development to final product manufacturing, providing clients with high-quality plastic component solutions.

Helping Our Customers

Customer Trust

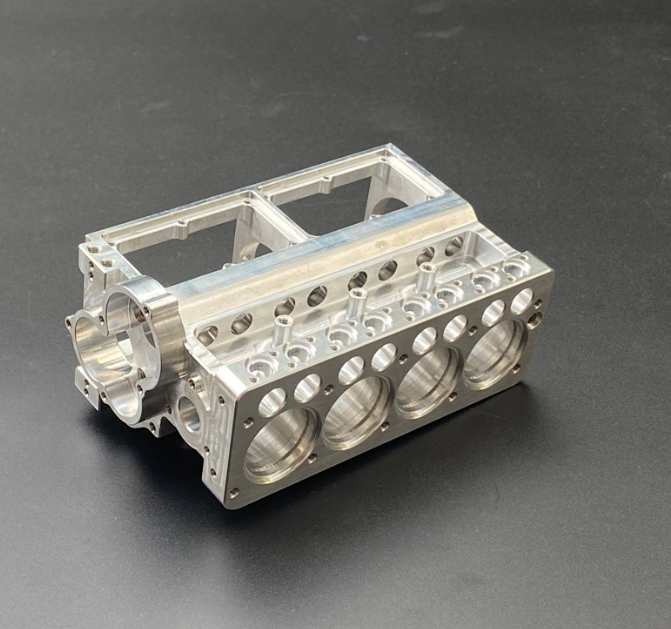

Rapid Prototyping in Three Days

This is an aluminum housing we crafted for a renowned automotive manufacturing company. Before partnering with XLC, they had tested the waters with numerous other prototyping firms. Unfortunately, every part they received had discrepancies during the dimensional inspection process. It was through a friend's referral that they found us.

What was the issue? Well, it was simply because the prototypes from these other services were not precise enough. Consequently, they had thought they would have to outsource from Europe. However, upon engaging with XLC, the company quickly discovered that they had finally found a service provider that could meet their exacting standards.