Precision Mold Making for Short-Run and Mass Production

Comprehensive Mold Making Solutions for Every Project

Need mold making supplies for mass production parts?

XLC is known as the best mold maker in China.

Our Key Strengths in Mold Making Services

While we conduct a preliminary design feasibility check during the quoting process, we also provide a fast and comprehensive Design for Manufacturability (DFM) report before production starts. This report identifies any potential errors or issues that could lead to manufacturing problems, ensuring a smooth production process.

We offer a wide range of mold types, eliminating the need to split your projects across multiple suppliers. Send all your requirements to us, and we’ll ensure your project runs seamlessly from start to finish.

With our extensive facility and advanced machining capabilities, we can build molds quickly, regardless of the application or material. This means you can get your moldings completed faster and bring your products to market sooner.

XLC can deliver your molds directly, but we also offer full-service injection molding and other production services. We can handle everything from prototypes to final parts using the molds we create, providing a one-stop solution for all your needs.

Discover why our customers choose us.

Mold Making Processes

Creating molds is a sophisticated process that demands expertise and precision. While each project has its unique requirements, a typical mold-making order generally follows these steps:

1. DFM

Once the customer confirms the mold order, we immediately begin an initial analysis of the part design to determine key elements such as the parting line and gate positions.

2. Mold design and mold flow analysis

The second step involves utilizing predictive modeling software to simulate how the molten material will flow within the mold. This allows us to identify and optimize any potential issues in the design.

3. CNC machining and EDM

We create the first set of molds using state-of-the-art machining tools, utilizing customer-specified materials like plastic, steel, aluminum, and more.

4. T1 sample

Using the newly created molds, we produce a T1 sample to provide a clear indication of how the final molded parts will appear and function, meeting the customer’s expectations.

5. Improvement if necessary

Based on the insights gained from the T1 sample, we conduct a thorough review of the mold design and implement any necessary modifications to enhance functionality and precision.

6. Commence production and shipping

We produce the molds according to the final specifications and then ship them to the customer.

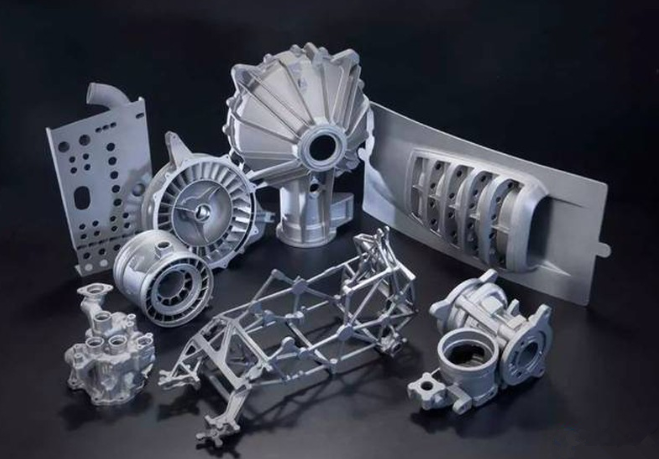

Types of Molds We are Offering

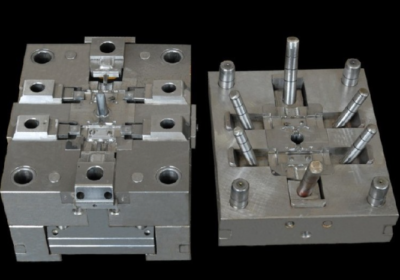

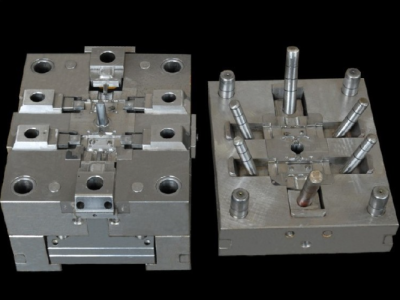

Injection injection mold

Plastic injection molds are precision tools crafted from aluminum or steel, designed to produce components from an extensive array of plastic materials. These materials include nylons, acrylics, elastomers, and even reinforced composites such as glass-filled polyamides. Customized plastic molds typically have a lifespan ranging from 100,000 to 1,000,000 shots, making them highly durable and reliable for large-scale production.

Die Casting Mold

Investment Casting Mold

We specialize in creating cost-effective investment casting molds by leveraging 3D printing technology to produce wax patterns, which are then encased in ceramic material. This innovative approach allows us to manufacture metal cast parts from a wide range of materials, including aluminum, zinc, magnesium, stainless steel, and more. By integrating 3D printing with traditional casting methods, we can significantly reduce production costs and lead times while maintaining high precision and quality.

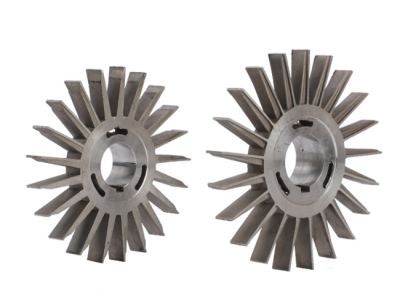

Metal Injection Mold

Metal Injection Molding (MIM) is a cutting-edge manufacturing process that combines the flexibility of plastic injection molding with the strength and durability of metal components. Typically, MIM molds are crafted from tool steel to withstand the high pressures and temperatures required during the injection process However, we also offer the option of using aluminum molds, which can provide cost-effective solutions without compromising on precision or qualityThis versatility allows us to cater to a wide range of applications and material requirements, including stainless steel, titanium, and aluminum, making MIM an ideal choice for producing complex, high-precision parts.

Sheet Metal Mold

Our extensive experience in designing and manufacturing sheet metal molds for stamping and bending enables us to create high-quality sheet metal prototypes with exceptional precision and efficiency. By leveraging advanced techniques such as CNC machining, laser cutting, and press brake bending, we ensure that each prototype meets the highest standards of accuracy and durability Whether you need complex geometries or custom designs, our capabilities cover a wide range of materials, including stainless steel, aluminum, and other metals, tailored to your specific requirements.

Extrusion Mold

Mold Making FAQ's

- High Production Volume: When you need to manufacture large quantities of products consistently and efficiently, a full automatic mold can significantly reduce production time and increase throughput。

- Complex and Consistent Quality Requirements: For products that require high precision and consistent quality, such as in semiconductor manufacturing or precision plastic parts, full automatic molds can minimize human errors and ensure uniformity。

- Cost Efficiency in Long-Run Production: Although the initial investment might be higher, full automatic molds can lower unit costs over time by reducing labor and operational costs, especially in large-scale production。

- Reduced Production Cycle Time: Full automatic molds can streamline the production process, reducing cycle times and improving overall factory efficiency。

- Advanced Manufacturing Integration: If your production process involves complex workflows or requires integration with other automated systems, a full automatic mold can be part of a comprehensive solution to optimize manufacturing。

Put your parts

into production today

All information and uploads are secure and confidential.