About xilici

One of the best rapid prototyping companies from China

Xilici is an ISO9001-2015 certified manufacturer, adhering to the 3E philosophy, namely Excellence, Efficiency and Economy, and has a professional team and the latest technology to ensure the success of your project. Whether you need to make complex parts with 3D visualization, or just want to present the final stage of your product at a top conference, Xilici can help you meet these needs

- Solution Consulting

- Top Project Management

- High Quality

- Time & Money Saving

What does xilici do?

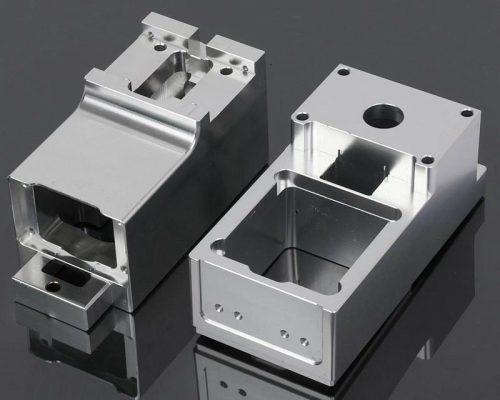

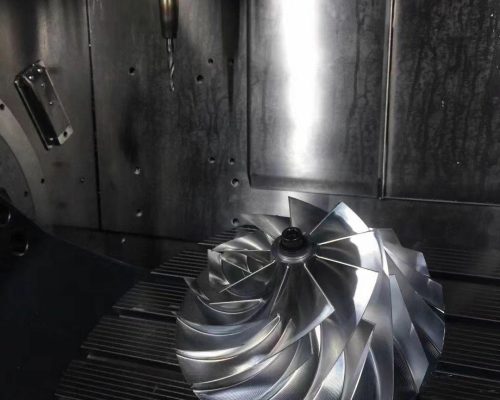

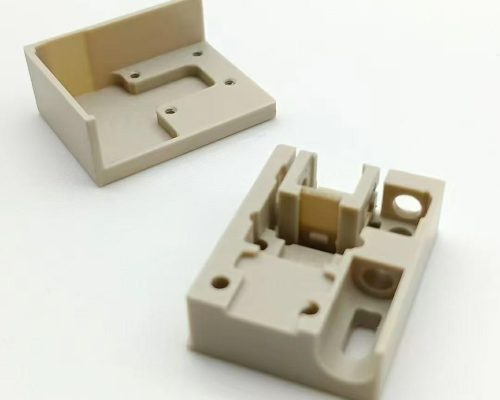

Xilici is committed to providing the highest quality rapid prototyping and low-volume manufacturing services, including: CNC machining, vacuum casting, die casting, 3D printing, rapid tooling and injection molding, sheet metal forming, plastic and aluminum extrusion.

We provide high quality manufacturing solutions that can have your design finished in a matter of hours. This gives you the opportunity to rigorously test your product, and make all the needed changes to perfect your design before it goes into full-scale production.

xilici teams

What can you expect

from xilici ?

At Xilici, we are dedicated to delivering comprehensive solutions that cater to a wide range of manufacturing needs. Our state-of-the-art manufacturing processes ensure that every customer receives a tailored solution for their specific requirements. We specialize in producing complex and precision parts, including optical components, automotive parts, medical devices, and aerospace components. Regardless of the complexity of your project, our skilled team and advanced technology enable us to deliver high-quality products that meet your exact specifications. Whether you need a single prototype or a large-scale production run, Xilici is equipped to handle your needs efficiently and effectively.

Saving money through our low-volume manufacturing process

Faster time to market (and a higher success rate)

Creating flexible design options for all your products

Supplying you with a comprehensive option for bridge production

View Our Factory and Facilities

At XLC, our manufacturing facilities are equipped with state-of-the-art technology to ensure precision and efficiency in every aspect of production. We utilize high-precision 3-, 4-, and 5-axis imported machines, which allow us to achieve tight tolerances and produce complex precision parts, including custom non-standard components. This capability is crucial for manufacturing precision mechanical parts that require exact specifications and high levels of accuracy.

Our commitment to quality is further demonstrated by our investment in a material tester. This equipment enables us to verify the materials used in each project, ensuring that they meet the specific requirements for precision mechanical parts. This step is vital for maintaining the integrity and performance of the final products.

Additionally, our automatic coordinate measuring machine (CMM) plays a significant role in our quality control process. It provides quick and accurate measurement results, allowing us to verify the dimensions and tolerances of each part efficiently. This ensures that every product we deliver meets the highest standards of quality and precision