AS9100D-Certified Aerospace Prototyping Services

AS9100-Certified Aerospace Manufacturing Solutions

Deliver mission-critical components through integrated 5-axis machining and metal additive manufacturing:

√ 72-hour prototyping (40% faster than industry average)

√ 0.005mm precision (AS9103 Level 3 compliance)

√ AI-powered cost optimization (15% hidden cost reduction)

Accelerate certification with digital thread technology:

Topology optimization (18-32% weight reduction)

CFD simulation (k-epsilon turbulence modeling)

Low-volume production (tooling-free for ≤50 units)

Our agile manufacturing ecosystem supports:

◼ Complex geometries (0.12mm/m curvature tolerance)

◼ Superalloy processing (1350℃ thermal resistance)

◼ Hybrid material assemblies (Ti-composite joints @892M

**XLC Aerospace Engineering Solutions**

With 10+ years of AS9100 Rev D-certified expertise, we accelerate aerospace innovation through:

√ 48hr rapid prototyping (5-axis CNC/SLM printing)

√ Elastic production scaling:

- 1-50pcs: $86/unit (NPI phase)

- 51-5Kpcs: JIT manufacturing

- 5K+pcs: automated cell production

Precision assurance:

• ISO 9001:2015 & NADCAP compliant

• 0.008mm dimensional tolerance (per EN 9100)

• 100% CMM inspection (Hexagon Absolute Arm)

Material mastery:

▶ Titanium alloys (Grade 5/23)

▶ PEEK composites (UL94 V-0)

▶ Inconel 718 (AMS 5662)

*Digital twin integration reduces development cycles by 35% vs traditional methods.*

Why Choose XLC for Aerospace Component Production?

2000+ Happy Customers

• ISO 9001:2015 & NADCAP compliant

2000+ Happy Customers

• ISO 9001:2015 & NADCAP compliant

2000+ Happy Customers

• ISO 9001:2015 & NADCAP compliant

Unparalleled Precision

Aerospace components demand exacting standards. XLC offers a level of precision that ensures every part is manufactured to the most stringent specifications. Whether it's the intricate geometry of engine parts or the complex structures of airframes, XLC delivers accuracy down to the micron level. This precision minimizes errors, reduces the need for rework, and ultimately enhances the overall quality and performance of the final product.

Superior Material Properties

The aerospace industry operates in extreme conditions—high altitudes, intense temperatures, and significant mechanical stresses. XLC is engineered to withstand these challenges. It exhibits exceptional strength - to - weight ratios, meaning components can be lighter without sacrificing durability. This not only improves fuel efficiency but also extends the operational lifespan of the aircraft. Additionally, XLC's resistance to corrosion and fatigue ensures that parts remain reliable over extended periods, even in harsh environments.

Advanced Manufacturing Techniques

XLC leverages state - of - the - art manufacturing processes that are specifically tailored for aerospace applications. These techniques, such as advanced additive manufacturing or precision machining, allow for the creation of complex shapes and structures that would be impossible with traditional methods. This flexibility enables designers to push the boundaries of what is possible, optimizing components for maximum performance and efficiency. Moreover, the integration of smart manufacturing technologies ensures consistent quality and traceability throughout the production process.

Timely Delivery and Production Efficiency

In the aerospace industry, timely delivery and production efficiency are critical. XLC's just - in - time (JIT) delivery model ensures that manufacturers receive the precise parts they need exactly when they need them. This approach reduces inventory costs, minimizes lead times, and streamlines operations. By integrating seamlessly into your production schedule, XLC helps maintain faster production cycles, reduces delays, and keeps projects on track. This flexibility and scalability allow manufacturers to adapt to varying production requirements without compromising quality

Cost - Effective Solutions

While aerospace manufacturing often comes with high costs, XLC offers a cost - effective alternative. Its precision and efficiency reduce material waste and minimize production time. The ability to create complex parts in fewer steps also lowers manufacturing costs. Furthermore, the extended lifespan and reduced maintenance requirements of XLC components translate to long - term savings for operators. This makes XLC a smart investment for aerospace companies looking to balance quality with affordability

Enhanced Safety and Reliability

Safety is paramount in aerospace. XLC's consistent quality and reliability contribute to the overall safety of aircraft. By using XLC, manufacturers can produce components that are less prone to failure. Rigorous testing and validation processes ensure that every part meets or exceeds industry - recognized safety standards. This gives both manufacturers and end - users the confidence that the components will perform as expected, even under the most demanding conditions.

Aerospace Prototyping and Manufacturing with XLC

Creating dependable aerospace part prototypes is a meticulous process that hinges on precision, top-tier quality, and unwavering adherence to detailed specifications. Over the years, we've honed our craft in aerospace prototyping, amassing a wealth of knowledge that enables us to craft a wide array of aerospace components, from straightforward to highly intricate designs. At XLC, we're committed to stringent quality assurance, conducting exhaustive checks and tests to ensure every part not only meets but exceeds customer expectations. Each component undergoes rigorous certification and testing protocols, guaranteeing reliability and performance. Ready to bring your designs to life? Request a quote or reach out to us to explore how we can partner with you in the aerospace sector.

What kind of aerospace & defense parts can we make?

- Seats

- Turbines

- Brakes

- Air Conditioning Systems

- Lighting System

- Night Vision Device

- Helmets

- Tank Model

- Engines

- Fastening Items such as Screws

- Electrical Parts

- Vacuum Pumps

- Gears

- Transmission Components

- Unmanned Aerial Vehicle

- Fuselages

- Tire Parts

- Radar Systems

- Fuel Pumps

- Wing Support

- Dashboard

- Teaching Aids

- Protective Gear

Aerospace manufacturing

processes

XLC provides a diverse array of manufacturing processes tailored for both aerospace prototyping and production components.

Injection Molding

Our services encompass both low - volume prototype moldings and high - volume mass production moldings, catering to diverse manufacturing needs..

CNC Machining

3D Printing

Sheet Metal Fabrication

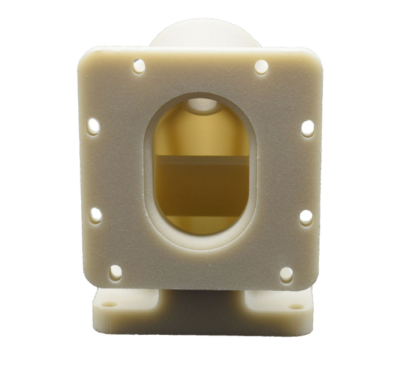

Aerospace Part

Gallery

Over the years, we have accumulated extensive experience in aerospace manufacturing, equipping us with the capability to tackle any aerospace project with confidence. Below is a showcase of our aerospace prototypes and production parts, crafted for clients around the globe.

Aerospace manufacturing materials

Aerospace manufacturing materials

Yes, XLC Rapid Prototyping is an ISO 9001:2015 certified manufacturer. We adhere to the highest quality management standards to ensure that every part we manufacture meets rigorous specifications, regardless of the project or customer. Our commitment to ISO 9001:2015 reflects our dedication to continuous improvement, customer satisfaction, and delivering products that consistently meet or exceed expectations

The delivery time for your parts depends on several factors, including the complexity of the design, the manufacturing process, and the current production schedule. For simple parts, we can often provide a turnaround time of 3-5 working days. For more complex projects, such as those involving injection molding or multi-step processes, the lead time may be longer, typically ranging from 1-2 weeks. We prioritize urgent orders and can expedite production if required. Please contact us with your specific requirements, and we will provide you with a detailed timeline.

Aerospace Faqs

Put your parts

into production today

All information and uploads are secure and confidential.