Elevate Your Automotive Innovation with Precision Prototyping and Production

Unlock the potential of your automotive vision with our top-tier prototyping and manufacturing solutions. We specialize in delivering bespoke, high-quality automotive prototypes and production components that meet the highest standards of precision and reliability. Our on-demand production model ensures that you can bring your products to market swiftly, mitigate risks, and optimize your production workflow—all at prices that offer unbeatable value. Accelerate your journey from concept to reality and drive your automotive projects forward with confidence

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

- Partner with Us for Quality and Reliability

Experience the Excellence of Automotive Prototyping and Manufacturing at XLC

1. Proven Expertise with Industry Leaders

2. Advanced Materials for Superior Performance

3. Cutting-Edge Rapid Prototyping Techniques

4. Rigorous Verification and Testing Procedures

5. Precision Engineering and Manufacturing Processes

Why manufacture

automotive parts

with XLC?

2000+ Happy Customers

IS0 9001

2015 certification

ISO certified

XLC Rapid Prototyping, as an ISO 9001:2015 certified manufacturer, is committed to delivering top-quality parts with unwavering consistency and stringent quality control, meeting the exacting standards of the industry.

Huge production capacity

We have the capability to handle orders of any size, ranging from single, custom-made devices tailored to individual patients, to large-scale production runs of standard components such as test tubes

Range of services

Our services encompass a wide array of manufacturing processes and an extensive selection of materials, including medically approved options such as titanium and silicone.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

With over a decade of experience in manufacturing medical parts, our skilled engineers are experts at optimizing your designs to achieve the best possible outcomes.

Easy quotation system

Our engineering team will promptly review your designs to deliver a swift and precise quotation for your project.

Transform Your Automotive Concepts into Reality with XLC

At XLC, we specialize in delivering cutting-edge rapid prototyping solutions tailored for the automotive industry. Our comprehensive services, including advanced CNC machining and 3D printing, empower automotive clients to swiftly turn their innovative ideas into tangible, high-quality prototypes.

Our team of experts brings a wealth of knowledge and technical expertise to every project. We understand the unique challenges and requirements of the automotive sector and are committed to providing solutions that accelerate product development, enhance performance, and ensure reliability. Whether you're developing a new vehicle component or refining an existing design, our capabilities are designed to support your needs from concept to completion.

To learn more about how XLC can enhance your automotive prototyping journey, or to receive a personalized quote, reach out to us today. Let us help you drive your innovations forward with precision and speed.

What kind of automotive parts can we make?

The automotive industry requires all sorts of parts made from both metals and plastics. Typical priorities for automotive customers include:

- Tight tolerances for critical parts and assemblies

- Wear-resistant materials with certifications

- Excellent quality control via on-machine inspection and/or CMM

Below are some of the types of automotive parts we can manufacture for you:

- Prototypes

- Electric vehicle and battery parts

- Custom body parts

- Lighting and lenses

- Replacement parts

- Jigs and fixtures

- Commercial/utility vehicle parts

- Bumpers

- Legacy/obsolete parts

- E-bike and scooter parts

- Dashboard and steering wheel components

- Engine parts

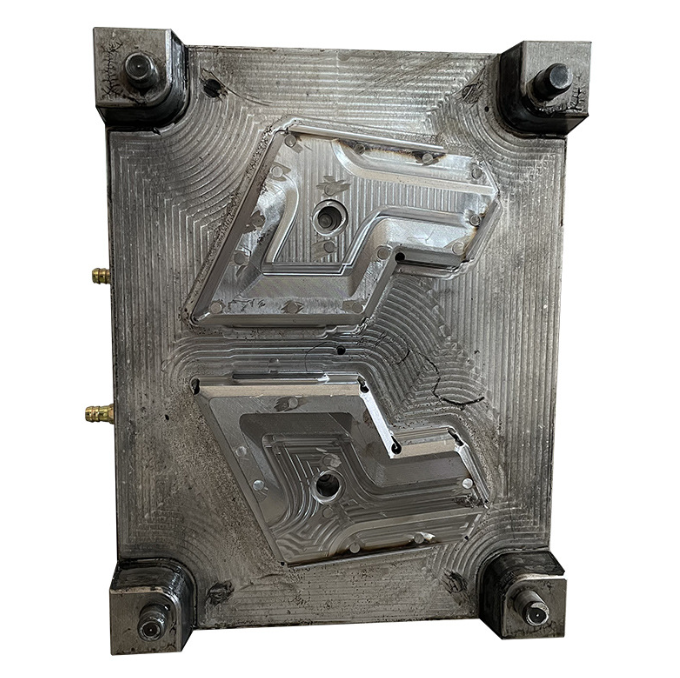

CCase research: car as a mud board assembly fast tool

Rapid Tooling & Injection Molding: Accelerating Production for Automotive Companies

At XLC, we leverage the powerful combination of rapid tooling and injection molding to offer automotive companies an efficient and flexible production solution. This technology duo significantly reduces lead times compared to traditional injection molding, making it ideal for small-batch production.Case Study: Efficient Manufacturing of Automotive Tail Lights

We recently completed a project where we manufactured hundreds of automotive tail light assemblies for a client. Each assembly included components such as the housing, reflector, light guide, bezel, outer lens, and other parts. By utilizing rapid tooling and injection molding, we not only ensured high-quality and consistent production but also saved the client significant time and cost. Here’s a closer look at how we achieved this:- Rapid Tooling: Using advanced rapid tooling techniques, we quickly developed and validated the molds. This approach is particularly well-suited for small-batch production and allows for a rapid response to customer needs.

- Injection Molding: Once the molds were ready, we employed high-precision injection molding processes to ensure dimensional accuracy and surface quality for each tail light component. The efficiency of injection molding enabled us to complete large-volume production in a short timeframe.

- Quality Control: Throughout the production process, we conducted 100% visual inspection for surface defects, ensuring that each product met the design requirements in both appearance and functionality.

Why Choose XLC?

- Quick Turnaround: Rapid tooling allows us to complete mold production in a fraction of the time compared to traditional methods, significantly shortening the production cycle.

- High-Quality Output: Our stringent production processes and quality checks ensure that every product meets the highest standards.

- Cost Savings: Small-batch production reduces mold costs and production risks, leading to substantial savings for our clients.

Aerospace manufacturing

processes

Injection Molding

Our services encompass both low - volume prototype moldings and high - volume mass production moldings, catering to diverse manufacturing needs.

CNC Machining

Leveraging advanced CNC milling and turning technologies, we are capable of crafting an extensive variety of prototypes and production components with precision and efficiency

3D Printing

We specialize in 3D printing services, utilizing a variety of advanced additive manufacturing technologies to produce high-quality parts in both metal and plastic materials.

Sheet Metal Fabrication

Precision laser cutting, expert bending, efficient stamping, seamless spinning, accurate punching, and reliable welding.

Aerospace Part Gallery

Over the years, we have accumulated extensive experience in the aerospace industry, equipping us with the expertise to tackle any aerospace project, no matter how complex. Our portfolio showcases a diverse range of aerospace prototypes and production parts that we have crafted for clients around the globe. Explore our gallery to see how we bring precision and innovation to aerospace manufacturing.

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Aerospace Faqs

Yes, XLC Rapid Prototyping is an ISO 9001:2015 certified manufacturer. We adhere to the highest quality management standards to ensure that every part we manufacture meets rigorous specifications, regardless of the project or customer. Our commitment to ISO 9001:2015 reflects our dedication to continuous improvement, customer satisfaction, and delivering products that consistently meet or exceed expectations

For specific manufacturing processes such as injection molding, we can initially provide a T1 sample for your parts. If needed, we can also supply additional samples to ensure your requirements are fully met.

The delivery time for your parts depends on several factors, including the complexity of the design, the manufacturing process, and the current production schedule. For simple parts, we can often provide a turnaround time of 3-5 working days. For more complex projects, such as those involving injection molding or multi-step processes, the lead time may be longer, typically ranging from 1-2 weeks. We prioritize urgent orders and can expedite production if required. Please contact us with your specific requirements, and we will provide you with a detailed timeline

Put your parts

into production today

All information and uploads are secure and confidential.