Express Custom CNC Machining Services

Experience our online CNC machining service, offering rapid prototyping and batch production of parts in metals and plastics. Get instant quotes now and enjoy cost-effective custom CNC machining services.

- Custom CNC Prototyping - Create one-of-a-kind CNC prototypes tailored to your design.

- Mass Production Capabilities - Support for mass production runs exceeding 500,000 units.

- Precision Tolerances - Achieve precision with tolerances as tight as ±0.005 mm to meet your exacting standards.

- Swift Delivery - Enjoy the fastest delivery in just 3 business days.

Upload Your Design Files - Simply upload your designs and embark on the journey to production.

STEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

- Your file security is our top priority; all uploads are strictly confidential.

Why Choose XLC for Custom CNC Machining Services?

XLC offers a comprehensive range of custom CNC machining services tailored for engineers, product developers, and designers. We specialize in rapid prototyping, small-batch machining, and high-volume production, ensuring that your needs are met with precision and efficiency. Here are the key reasons why XLC should be your manufacturing partner:

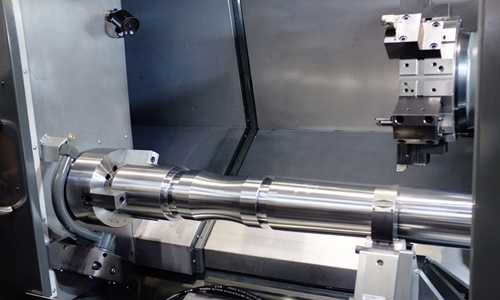

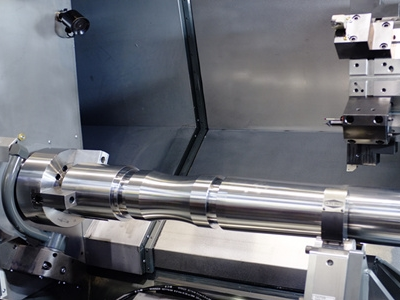

Advanced In-House Equipment: Our facilities are equipped with state-of-the-art HAAS CNC mills and lathes, Hexagon CMMs, and Olympus XRF analyzers. This advanced technology guarantees that your CNC parts are manufactured with the correct materials and precise dimensions.

Expertise in Precision Parts: Our experienced engineers have a deep understanding of CNC machining, having worked on numerous projects across various industries. They are adept at handling complex geometries and tight tolerances, ensuring that your precision mechanical parts and custom non-standard components meet the highest standards.

Quality Assurance: Every part undergoes rigorous inspection by our quality control department before shipment. This ensures that each CNC machined part is built to specification and free of defects, providing you with consistent high-quality results.

Fast Turnaround Times: Leveraging our in-house capabilities and a network of qualified manufacturing partners, XLC can deliver fast turnaround times. Whether you need a single prototype or a large-scale production run, we can meet your deadlines efficiently.

Customized Solutions: We understand the unique requirements of each project and provide customized solutions to meet your specific needs. Our flexible approach allows us to adapt quickly to your changing requirements, ensuring that your project is successful from start to finish.

By choosing XLC, you gain access to a reliable and efficient manufacturing partner that can deliver high-quality CNC machined parts with precision and speed.

CNC Machining Process Elaboration

CNC machining, or Computer Numerical Control machining, is a highly automated manufacturing process that utilizes computer-controlled tools to create precise and complex parts from various materials. This process has revolutionized the manufacturing industry due to its efficiency, precision, and versatility. Here is a detailed exploration of the CNC machining process, its applications, challenges, and future trends.

Basic Principles of CNC Machining

At its core, CNC machining involves the use of computer programs to control the movement of tools and workpieces. The process begins with a CAD (Computer-Aided Design) model, which is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains detailed instructions for the machine, specifying the tool paths, speeds, and other parameters required to shape the workpiece into the desired part.

The CNC machine, equipped with high-precision cutting tools, follows these instructions to remove material from the workpiece. Depending on the complexity of the part, CNC machines can have multiple axes, allowing for intricate movements and precise cuts. For instance, a 5-axis CNC machine can move the tool and workpiece in five different directions simultaneously, enabling the creation of complex three-dimensional shapes.

Applications of CNC Machining

CNC machining is widely used across various industries due to its ability to produce high-quality parts with tight tolerances and complex geometries. Here are some key applications:

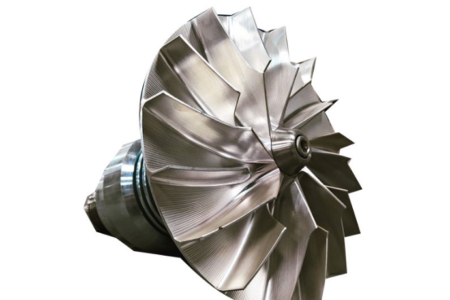

Aerospace: In the aerospace industry, CNC machining is crucial for producing components that require extreme precision and reliability, such as turbine blades, landing gear parts, and engine components. The ability to maintain strict tolerances ensures the safety and performance of these critical parts.

Automotive: The automotive sector relies heavily on CNC machining for the production of engine components, transmissions, and other parts. The high repeatability of CNC machining ensures that each part is identical, which is essential for maintaining the quality and performance of vehicles.

Electronics: In the electronics industry, CNC machining is used to create intricate components such as circuit boards and semiconductor parts. The precision of CNC machining allows for the miniaturization of electronic devices, enabling the development of smaller and more powerful gadgets.

Medical Equipment: CNC machining plays a vital role in the production of medical devices, including surgical instruments, implants, and diagnostic equipment. The high precision and consistency of CNC machining ensure that these devices meet the stringent quality and safety standards required in the medical field.

Challenges in CNC Machining

Despite its many advantages, CNC machining also faces several challenges:

High Initial Costs: The equipment and software required for CNC machining are expensive, which can be a barrier for small to medium-sized enterprises. However, leasing options and government subsidies can help mitigate these costs.

Skilled Labor Requirements: Operating CNC machines requires skilled technicians who understand both the hardware and software aspects of the system. The shortage of qualified personnel can lead to inefficiencies and increased labor costs.

Tool Wear and Maintenance: Tool wear is a common issue that affects the precision and efficiency of CNC machining. Regular maintenance and the use of high-quality tools are essential to extend tool life and maintain machining accuracy.

Complex Programming: Programming a CNC machine involves creating detailed instructions that must be error-free. This requires advanced software and skilled programmers to optimize the machining process and avoid costly mistakes.

Future Trends in CNC Machining

The CNC machining industry is continuously evolving, driven by technological advancements and changing market demands. Some notable trends include:

Automation and Integration: Increasingly, CNC machines are being integrated with other systems, such as CAD/CAM software and automated material handling systems, to create fully automated production lines. This integration enhances efficiency and reduces human error.

Advanced Materials and Processes: As new materials with unique properties are developed, CNC machining processes are being adapted to accommodate them. For example, the machining of exotic alloys and composites requires specialized tools and techniques to ensure optimal results.

Sustainability and Green Manufacturing: There is a growing focus on making CNC machining more sustainable by optimizing processes to reduce waste, energy consumption, and environmental impact. This includes the development of eco-friendly cutting fluids and the use of energy-efficient machines.

In conclusion, CNC machining is a versatile and essential manufacturing process that offers numerous benefits, including high precision, efficiency, and flexibility. Despite the challenges it faces, the continuous advancement of technology and the increasing demand for complex, high-quality parts ensure that CNC machining will remain a critical component of modern manufacturing for years to come.

Our CNC Machining Capabilities

We are always ready for the challenges of tight tolerances and complex CNC machined parts. Try out our precision CNC machining services and become our next satisfied customer.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

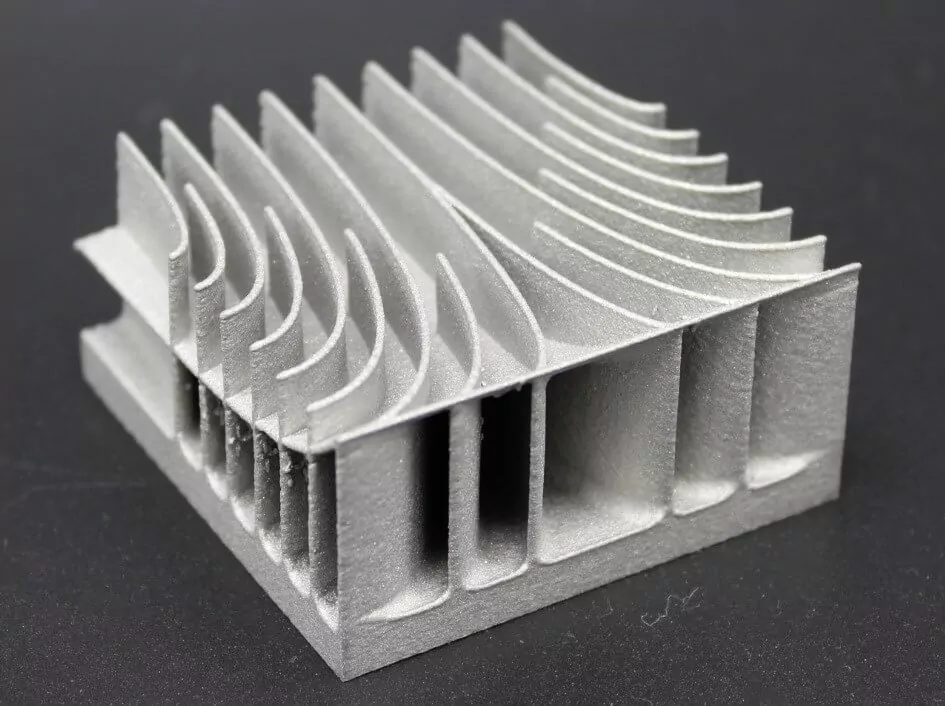

CNC Machining Excellence in Action

Explore our gallery of expertly crafted CNC machined parts, a testament to our precision and innovation. With XLC, we cater to a wide array of CNC machining needs, ensuring your project's success.

Precision in CNC Machining: Tolerance Standards, Material Options, and Surface Polishing

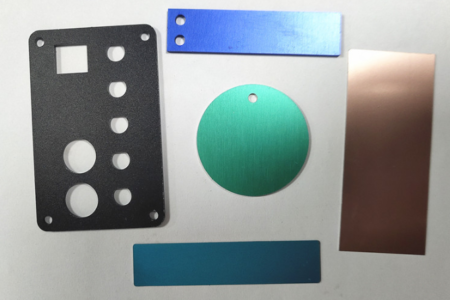

Surface Oxidation Process

Surface oxidation is a chemical treatment that enhances the durability and appearance of metal parts. It involves the creation of a thin oxide layer on the metal's surface, which provides corrosion resistance, increased hardness, and can also be used for decorative purposes. This process is commonly used in industries where metal components are exposed to harsh environments or require a specific aesthetic finish.

Mechanical Tolerances

Mechanical tolerances are the allowable variations in dimensions of a manufactured part. They ensure that components fit together correctly and function as intended within a machine or assembly. Tolerances account for factors like material expansion, wear, and manufacturing processes, and are critical for maintaining precision and quality in engineering designs.

The Choice of Raw Materials: A Key to Workpiece Success

Selecting the right raw materials is pivotal for workpiece durability, functionality, cost-efficiency, and aesthetics, as it directly impacts the machining process and the final product's quality.

Put your parts

into production today

All information and uploads are secure and confidential.

CNC Machining

FAQs

是的。一旦我们收到您的 RFQ,我们的工程师将立即审查 CAD 文件,并在需要时提供 CNC 加工的设计反馈和优化建议。为了获得更好的 CNC 加工零件质量并找出影响单价的 CNC 加工成本的要点。

xlc 拥有两家 CNC 加工车间,拥有 60 多台 CNC 铣床和 CNC 车床。我们拥有 40 多名经验丰富的技术专家,因此我们可以保证内部生产 5000 件不同类型的 CNC 加工零件。除此之外,得益于我们制造网络中经过验证的制造合作伙伴,我们可以无限地提供额外的 CNC 加工零件。

xlc 是中国质量、速度和客户服务方面最好的 CNC 加工公司之一。凭借高品质的 CNC 机器,我们可以轻松实现 +/- 0.02 毫米的公差,甚至可以达到 +/- 0.01 毫米以内。但请记住,这可能会影响成本。

我们的生产工程师会审查从客户那里收到的每份 RFQ,以确保正确计算材料和 CNC 加工成本。大多数制造平台的在线 CNC 加工报价系统还不够准确。阅读有关案例研究的更多信息。

参照我们之前的 CNC 加工订单,超过 90% 的订单在 7 天内完成。简单的 CNC 加工零件可以在 2 天内完成,而复杂或大型 CNC 加工零件可能需要 15 天以上。数量是另一个需要考虑的问题。通过我们的 CNC 加工制造网络,我们还可以从靠近您在美国和欧洲所在地的 CNC 加工车间加工您的零件,从而缩短运输时间。

Advantages and Challenges of CNC Machining

在 CNC 加工过程中,简单零件比复杂零件更经济。虽然几何复杂性是可能的,但它需要增加操作成本的步骤,例如多轴加工或多个设置。设计复杂性受到刀具访问的限制:切削刀具的角度和尺寸决定了它可以和不能到达工件的哪些区域。CNC 加工的启动成本也可能很高。虽然它是一种无工具过程,使其启动成本低于模塑和铸造,但加工需要缓慢的设置和刀具装载程序,只有经验丰富的机械师才能执行。如果每个设置只加工一个或少数几个零件,这会大大增加每个零件的成本。CNC 加工的另一个挑战是材料浪费。由于加工是一种减材过程,因此相当一部分工件会变成切屑(切屑),加工后丢弃。但是,毛坯(用于加工的原材料)的成本比其他一些形式的材料(例如增材制造粉末)低得多。

Simple parts are more economical than complex ones during CNC machining. While geometric complexity is possible, it requires steps that increase the cost of the operation, such as multi-axis machining or multiple setups. Design complexity is limited by tool access: the angle and size of the cutting tool determines which areas of the workpiece it can and cannot reach. Startup costs can also be high for CNC machining. Although it is a tool-free process, giving it lower startup costs than molding and casting, machining requires a slow setup and tool loading procedure that only an experienced machinist can perform. This adds significant cost per part if only one or a handful of parts are machined per setup. Another challenge for CNC machining is material waste. Because machining is a subtractive process, a considerable amount of the workpiece is turned into chips (swarf) that are discarded after machining. However, blanks (pieces of raw material for machining) cost much less than some other forms of material — additive manufacturing powders, for example.

CNC Machining for Various Industrial Applications

Our CNC machining service have been qualified by worldwide customers from different industries. We have been offering CNC machined parts for various industries which include the below list and more.

Automotive

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Shipbuilding

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Aerospace

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

New Energy

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

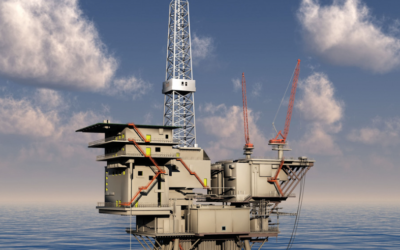

Drilling Rig

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Equipment

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

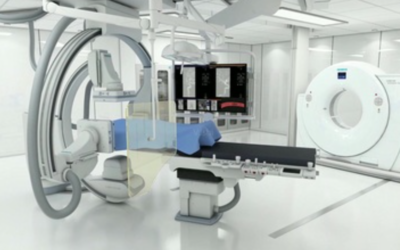

Medical

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Aircraft

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.