Energy Prototyping & Manufacturing

Obtain top-tier manufacturing services for your custom energy prototypes and production components. Accelerate product launch, mitigate risks, and optimize production processes with on-demand manufacturing at competitive rates

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

- Rapid turnaround times for urgent projects

Why manufacture

energy parts

with XLC?

2000+ Happy Customers

IS0 9001

2015 certification

ISO certified

XLC Rapid Prototyping, as an ISO 9001:2015 certified manufacturer, is committed to delivering top-quality parts with unwavering consistency and stringent quality control, meeting the exacting standards of the industry.

Huge production capacity

We have the capability to handle orders of any size, ranging from single, custom-made devices tailored to individual patients, to large-scale production runs of standard components such as test tubes.

Range of services

Our services encompass a wide array of manufacturing processes and an extensive selection of materials, including medically approved options such as titanium and silicone.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

With over a decade of experience in manufacturing medical parts, our skilled engineers are experts at optimizing your designs to achieve the best possible outcomes.

Easy quotation system

Our engineering team will promptly review your designs to deliver a swift and precise quotation for your project.

Robust materials

We deliver exceptional material quality, ranging from machined superalloys such as Inconel to precision die-cast aluminum.

Unlock the Future of Energy Innovation with XLC

The energy sector thrives on innovation, rapid production, and superior quality. At XLC, we empower energy industry clients with advanced rapid prototyping solutions and precision services such as CNC machining and sheet metal fabrication. Our team of experts leverages their extensive knowledge and skills to transform innovative concepts into reality, driving progress and efficiency in the energy space.

What kind of energy parts can we make?

The energy industry requires a broad range of parts, large and small, made from both metals and plastics. Typical requirements for the energy sector include:

- Tight tolerances for critical parts and assemblies.

- Wear-resistant, weather-resistant, and chemically resistant materials with.

Certifications

- High-strength metal parts for large-scale equipment.

- Consistency throughout large batches of parts.

Below are some of the types of parts we can manufacture for customers in the energy sector:

- Prototypes

- Housings

- Battery components

- Valves

- Machine and tool parts

- Moving parts

- Pumps and accessories

- Parts for tractors, bulldozers, forklifts

- Solar panel parts

- Jigs and fixtures

- Ducts and ventilation

- Generator components

- Automation parts

- Casings

- Conveyors and conveying equipment

- Pipes

- Heat exchangers

- Turbine components

- Frames

- Replacement parts

- impellers

- Seats

Aerospace manufacturing

processes

At XLC, we provide an extensive array of manufacturing processes tailored for aerospace prototypes and production components.

Injection Molding

Our services encompass both low - volume prototype moldings and high - volume mass production moldings, catering to diverse manufacturing needs.

CNC Machining

Leveraging advanced CNC milling and turning technologies, we are capable of crafting an extensive variety of prototypes and production components with precision and efficiency.

Sheet Metal Fabrication

Precision laser cutting, expert bending, efficient stamping, seamless spinning, accurate punching, and reliable welding

3D Printing

We specialize in 3D printing services, utilizing a variety of advanced additive manufacturing technologies to produce high-quality parts in both metal and plastic materials.

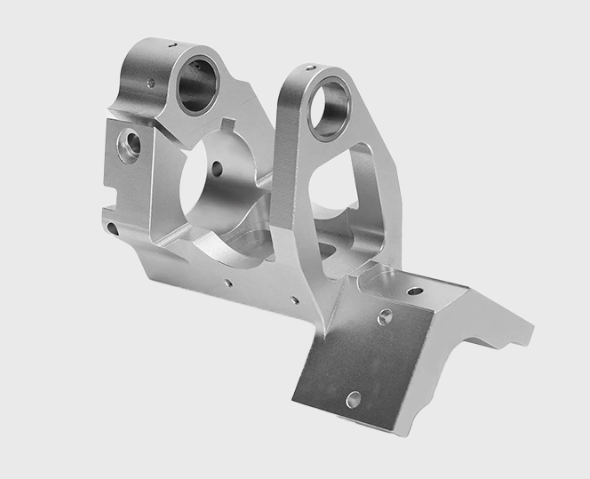

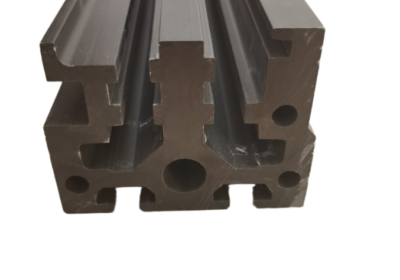

Industrial Machinery Part Gallery

Over the years, we have accumulated extensive experience in handling a wide range of industrial machinery projects. Our expertise allows us to deliver high-quality prototypes and production parts that meet the most demanding requirements. Below is a showcase of our industrial machinery prototypes and production parts, crafted for clients around the globe.

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Energy Industry Faqs

Yes, XLC Rapid Prototyping is an ISO 9001:2015 certified manufacturer. We adhere to the highest quality management standards to ensure that every part we manufacture meets rigorous specifications, regardless of the project or customer. Our commitment to ISO 9001:2015 reflects our dedication to continuous improvement, customer satisfaction, and delivering products that consistently meet or exceed expectations

For specific manufacturing processes such as injection molding, we can initially provide a T1 sample for your parts. If needed, we can also supply additional samples to ensure your requirements are fully met.

The delivery time for your parts depends on several factors, including the complexity of the design, the manufacturing process, and the current production schedule. For simple parts, we can often provide a turnaround time of 3-5 working days. For more complex projects, such as those involving injection molding or multi-step processes, the lead time may be longer, typically ranging from 1-2 weeks. We prioritize urgent orders and can expedite production if required. Please contact us with your specific requirements, and we will provide you with a detailed timeline

Put your parts

into production today

All information and uploads are secure and confidential.