Medical Prototyping & Manufacturing

Accelerate your medical product journey with our top-tier prototyping and manufacturing services. We deliver high-quality custom medical prototypes and production parts, ensuring faster launch, reduced risks, and streamlined processes. Benefit from competitive pricing and on-demand production to bring your innovations to market efficiently..

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

- Partner with Us for Quality and Reliability

- Accelerated Time-to-Market: Leveraging advanced design concepts and efficient manufacturing processes, we can rapidly transform your ideas into tangible products. Through rapid prototyping and iterative design, we ensure a swift transition from concept to market.

- Risk Reduction: Our experienced team specializes in medical device design, development, and manufacturing, adhering strictly to ISO and QSR compliance standards to ensure product quality and safety.

- Optimized Production Processes: We provide one-stop services from conceptual design to large-scale manufacturing, ensuring seamless integration across all stages. Utilizing lean manufacturing and automation technologies, we enhance production efficiency and reduce costs.

- Product Design & Development: We offer full-service support from conceptual design to detailed engineering specifications, helping you develop medical products that meet market demands.

- Prototyping & Testing: Using rapid prototyping technologies, we can quickly produce testable prototypes to gather user feedback and optimize your product.

- Large-Scale Production: Our global manufacturing network and state-of-the-art facilities can meet your production needs from low to high volumes, ensuring product quality and on-time delivery.

- Expert Team: Our engineers and manufacturing specialists have extensive experience in the medical device field, providing you with professional technical support.

- Cost-Effective: Through design optimization and lean manufacturing, we effectively reduce production costs while maintaining high-quality standards.

- Global Footprint: Our global manufacturing bases offer flexible production options, ensuring rapid delivery of your products.

Why manufacture

medical parts

with XLC?

2000+ Happy Customers

IS0 9001

2015 certification

ISO certified

XLC Rapid Prototyping, as an ISO 9001:2015 certified manufacturer, is committed to delivering top-quality parts with unwavering consistency and stringent quality control, meeting the exacting standards of the industry.

Huge production capacity

We have the capability to handle orders of any size, ranging from single, custom-made devices tailored to individual patients, to large-scale production runs of standard components such as test tubes.

Range of services

Our services encompass a wide array of manufacturing processes and an extensive selection of materials, including medically approved options such as titanium and silicone.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

With over a decade of experience in manufacturing medical parts, our skilled engineers are experts at optimizing your designs to achieve the best possible outcomes.

Easy quotation system

Our engineering team will promptly review your designs to deliver a swift and precise quotation for your project.

At XLC, our expert team is well-equipped with the skills and experience to fulfill your medical part orders, regardless of the technology or material required. Whether you need prototypes for initial testing or production parts for market launch, we can deliver high-quality solutions tailored to your specific needs. Our advanced manufacturing capabilities, combined with a focus on precision and compliance, ensure that your medical components meet the highest standards of quality and safety.

We invite you to request a quote for your designs or contact us to discuss how we can collaborate with you in the medical industry. Our goal is to provide comprehensive support, from design and prototyping to full-scale production, helping you accelerate your product development and bring innovative medical solutions to market efficiently.

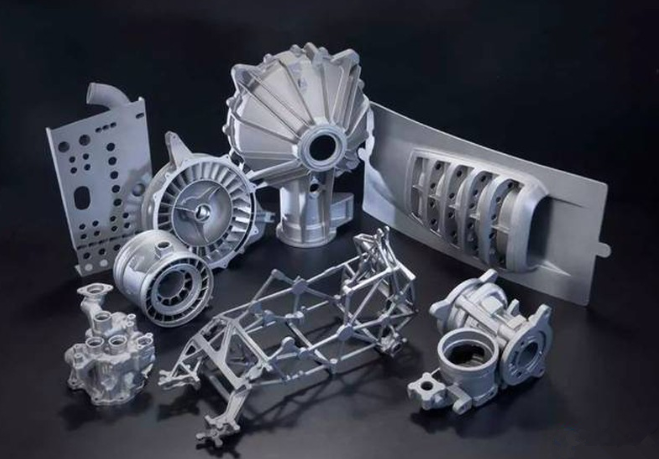

What kind of medical parts can we make?

The medical and healthcare industry requires a broad range of parts and prototypes made from a range of materials. These include parts that are expected to make contact with the human body and those that are used in machinery and equipment used by medical professionals. Typical requirements include:

- Tight tolerances for critical parts and assemblies

- Materials that are biocompatible, non-toxic, or sterilizable

- Quality control via on-machine inspection and/or CMM

Below are some of the types of medical parts we can manufacture for you:

- Prototypes

- Surgical instruments

- Tables and panels

- Electronic equipment components

- Fluid management systems

- Handheld devices

- Care equipment

- Anatomical models

- MRI and X-Ray components

- Medical carts

- Prostheses

- Biotechnology components

- Diagnosis equipment

- Replacement parts

- Monitoring equipment components

- Physiotherapy apparatuses

- Medical delivery systems

- Respiratory devices

- Ultrasonic equipment

Aerospace manufacturing

processes

CNC Machining

Leveraging advanced CNC milling and turning technologies, we are capable of crafting an extensive variety of prototypes and production components with precision and efficiency

Injection Molding

Our services encompass both low - volume prototype moldings and high - volume mass production moldings, catering to diverse manufacturing needs.

3D Printing

We specialize in 3D printing services, utilizing a variety of advanced additive manufacturing technologies to produce high-quality parts in both metal and plastic materials.

Liquid Silicone Rubber Molding

With years of accumulated expertise, we have honed our capabilities to tackle the most complex aerospace projects. Explore our gallery showcasing a diverse range of aerospace prototypes and production parts crafted for clients around the globe.

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Medical Faqs

Yes, XLC Rapid Prototyping is an ISO 9001:2015 certified manufacturer. We adhere to the highest quality management standards to ensure that every part we manufacture meets rigorous specifications, regardless of the project or customer. Our commitment to ISO 9001:2015 reflects our dedication to continuous improvement, customer satisfaction, and delivering products that consistently meet or exceed expectations

The delivery time for your parts depends on several factors, including the complexity of the design, the manufacturing process, and the current production schedule. For simple parts, we can often provide a turnaround time of 3-5 working days. For more complex projects, such as those involving injection molding or multi-step processes, the lead time may be longer, typically ranging from 1-2 weeks. We prioritize urgent orders and can expedite production if required. Please contact us with your specific requirements, and we will provide you with a detailed timeline

Put your parts

into production today

All information and uploads are secure and confidential.