Precision CNC Machining for Metals & Plastics

Unlock complexity and precision for all your machining needs

When you are looking for precision machining services, you should never compromise on quality, as only high-quality machining can produce parts that meet your stringent requirements. At XLC, you will find a range of high-end precision CNC machining services waiting for you. We have a team of highly skilled professionals who have accumulated extensive experience in using 3-, 4-, and 5-axis CNC machines for project machining, and they can precisely grasp every detail. XLC offers a variety of services including CNC milling, CNC turning, EDM, wire EDM, and surface grinding. We control the manufacturing process of prototypes and parts from a technical perspective, allowing you to focus entirely on the market promotion of your products without being distracted by technical challenges.

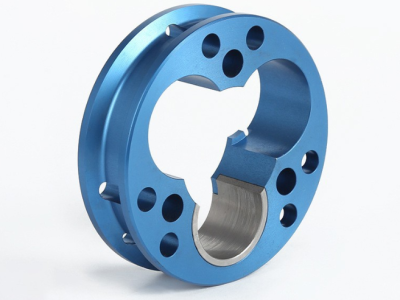

Professional aluminum products processing

At XLC, our state-of-the-art CNC machines boast robust spindles, enabling us to swiftly slice through aluminum, making them perfect for crafting components like enclosures. Yet, by equipping these high-RPM machines with diminutive cutting tools, we're also adept at churning out parts that boast a premium machined finish and intricate details, such as aluminum reflectors and mold cores.

Our expertise in both swift material removal and meticulous detailing empowers us to manufacture an array of aluminum machined parts, spanning from the straightforward to the complex, and from the petite to the sizable. Moreover, we're highly adaptable. Whether it's a one-time aluminum machined prototype that requires a swift turnaround or a bulk order of bespoke aluminum components with a cost-effective per-unit price, we're up to the task.

Reasons to choose our precision machining

In a large number of precision machining suppliers. Meeting your requirements should be considered in the following directions

Five advantages of XLC company’s 5-axis precision machining

Among many precision machining manufacturers, the following 4 reasons are why you should choose us

Quick turnaround

With 15 in-house 5-axis machines, we have the ability to create your prototypes and production parts in days.

Quick quote and design

Our company has 10 technical engineers who have been in the industry for 20 years. They can quickly make quotations and provide technical discussions.

Quality assurance

A variety of measuring equipment, three-dimensional coordinates, projectors, hardness testers, flaw detectors, etc. to provide customers with high-quality products

industry compatibility

Our products cover aerospace, automobiles, new energy, ships, etc. We have close cooperation with various industries

Advantages of Precision Machining

Precision machining is an essential manufacturing process that enables companies to produce the most delicate parts with the tightest tolerances imaginable. Here are just some of its main advantages over alternative approaches:

High Precision

As the name implies, precision molding offers unparalleled accuracy, producing consistent quality with every part that is produced.

Minimal Errors

Because precision machining uses CNC technology, it is largely automated and reduces the probability of error to a minimum.

Efficiency

Because of the automated nature of the process, precision CNC machining can produce parts very efficiently and with minimal workforce intervention.

Less Waste

Precision machining produces minimal waste, allowing to save on materials and maintain environmentally-friendly manufacturing practices.

Cost-Effective

The high-tech nature of the process also means that there’s less waste, less labor, and a low chance of error, which makes it one of the most cost-effective manufacturing methods.

Put your parts

into production today

Precision Machining

FAQ's

When designing parts, some engineers suggest very tight tolerances, far more than are actually needed. That’s not an ideal approach. If +/-0.05mm works, opting for +/-0.01mm tolerance will increase the manufacturing cost many times. However, when you do need tolerances as tight as 0.01mm, then you can’t beat the accuracy and consistency offered by precision machining.

There’s a wide range of materials that can be used in precision machining – you can use aluminum brass, copper, steel, titanium, as well as rigid plastics like PPS, PEEK. Reach out to learn more about the types of materials that are available when using precision machining technology.

We use high-quality machines for precision CNC milling & turning, precision EDM, precision grinding, and a range of other tools in house, using AC to stabilize the workshop temperature. That, combined with the experience and qualifications of our engineers, as well as rigorous inspection of machines and processes, ensures consistent quality even in the most demanding scenarios.

Put your parts

into production today

All information and uploads are secure and confidential.